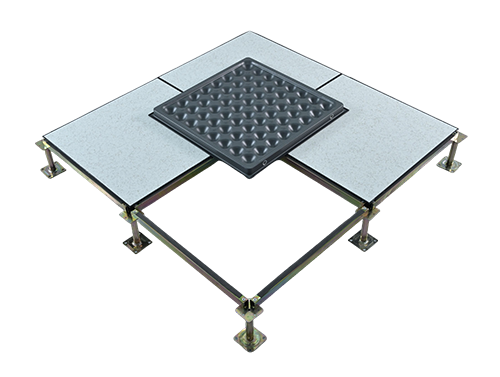

Corrosion-Resistant All-Steel Anti-Static Floor: A Durable, Efficient Solution for High-Tech Environments

The corrosion-resistant all-steel anti-static floor is a cutting-edge flooring solution engineered to meet the demanding needs of industries where static control and long-term durability are paramount. Constructed from high-quality steel with advanced corrosion-resistant coatings, this floor not only provides superior protection against electrostatic discharge (ESD) but also offers exceptional performance in challenging environments. From data centers and clean rooms to industrial manufacturing plants, this anti-static floor ensures optimal safety, efficiency, and longevity. In this article, we’ll delve into the energy-saving effects, solutions provided by this flooring, along with maintenance tips and usage recommendations to maximize its performance and lifespan.

The corrosion-resistant all-steel anti-static floor is designed to withstand even the harshest conditions, making it ideal for environments prone to moisture, chemicals, or high wear. Whether used in manufacturing plants or coastal areas with high humidity, the floor’s special coating ensures that the steel remains free from rust and degradation, thus maintaining its structural integrity and aesthetic appeal over time.

One of the most significant benefits of this flooring is its ability to control electrostatic discharge (ESD). The floor dissipates static charges efficiently, protecting sensitive electronic equipment, machinery, and components from damage caused by electrical discharge. This makes it a perfect choice for clean rooms, server rooms, and industries where static electricity can lead to costly malfunctions or product defects.

Made from high-strength steel, the corrosion-resistant all-steel anti-static floor can support heavy equipment, machinery, and foot traffic without compromising on performance. This makes it highly durable and suitable for industries that require flooring capable of withstanding significant weight without showing signs of wear or failure.

The corrosion-resistant all-steel anti-static floor helps maintain temperature control in high-tech environments by offering effective thermal conductivity. This ensures that HVAC systems do not have to work as hard to maintain optimal temperatures. By stabilizing the ambient temperature, energy usage is reduced, leading to cost savings over time.

This flooring solution’s resistance to corrosion and wear means fewer repairs and replacements are needed, reducing maintenance costs. With less downtime required for floor repairs, operations can run smoothly and energy usage is kept to a minimum since equipment is less likely to be impacted by static-related damage.

Due to its reflective surface, the corrosion-resistant all-steel anti-static floor helps improve lighting efficiency in indoor environments. The reflective properties of the steel help disperse light more evenly across the workspace, reducing the need for additional artificial lighting and contributing to lower energy consumption.

By installing a corrosion-resistant all-steel anti-static floor, businesses can protect valuable electronic equipment from costly ESD damage. This flooring effectively neutralizes static electricity, preventing it from accumulating on sensitive machinery and components. This solution is especially beneficial for industries such as:

Data Centers: Protect servers, routers, and other critical devices.

Electronics Manufacturing: Safeguard components during production.

Clean Rooms: Ensure contamination-free environments for sensitive processes.

This flooring is perfect for environments that require both durability and resistance to external factors such as moisture, high humidity, and chemical exposure. Its corrosion-resistant coating ensures the floor remains intact and functional, even in industries like food processing, pharmaceuticals, and automotive manufacturing.

While the initial investment in corrosion-resistant all-steel anti-static flooring might be higher than conventional flooring, the long-term benefits far outweigh the costs. With its exceptional durability and minimal maintenance requirements, this flooring significantly reduces replacement and repair costs over the years, providing a great return on investment.

Proper maintenance is essential for ensuring the long-lasting performance of corrosion-resistant all-steel anti-static flooring. Here are the key maintenance tasks to ensure optimal floor condition and functionality:

Dust and debris can accumulate on the floor surface, which may interfere with its anti-static performance. A damp mop with a mild detergent should be used for daily or weekly cleaning. It’s important to avoid harsh chemicals or abrasives that could damage the surface or interfere with the electrostatic discharge properties.

While corrosion-resistant coatings offer substantial protection, it’s important to conduct periodic inspections to ensure that there are no signs of wear or damage to the surface. Look for:

Cracks or dents: Structural integrity should be maintained, especially in high-traffic areas.

Static performance: Verify that the anti-static properties are functioning as intended.

Surface condition: Check for any discoloration or roughness that could indicate deterioration.

Minor scratches or chips can be repaired using touch-up kits designed specifically for corrosion-resistant all-steel anti-static floors. For more significant damages, it is recommended to consult a professional to ensure proper repairs are made without compromising the floor’s protective properties.

Regularly apply a protective coating or sealant to the floor to enhance its durability and corrosion resistance. This will help maintain the floor's appearance and extend its lifespan. Preventative maintenance also includes monitoring the humidity and temperature in the environment, as extreme conditions can affect the performance of anti-static floors.

To maximize the effectiveness of the corrosion-resistant all-steel anti-static floor, ensure the environment maintains stable temperature and humidity levels. Extreme fluctuations can affect the floor’s performance, so it’s essential to maintain controlled conditions in industries like electronics manufacturing, data centers, and clean rooms.

If the floor is to be used in areas with heavy machinery or equipment, ensure that the weight load does not exceed the floor's specified load-bearing capacity. Overloading the floor can cause deformation or damage, reducing its effectiveness and longevity.

While the corrosion-resistant all-steel anti-static floor is designed to withstand heavy foot traffic, using protective mats or pads in high-traffic zones can help distribute the load and prevent wear on the floor. Additionally, ensuring that employees wear clean shoes can minimize dirt and debris that could interfere with the floor’s performance.

The corrosion-resistant all-steel anti-static floor offers a robust, long-lasting solution for industries that require both static control and durability. With its corrosion-resistant properties, superior ESD protection, energy-saving effects, and low maintenance needs, it proves to be a wise investment for businesses in data centers, clean rooms, and manufacturing environments. By following the recommended maintenance guidelines and usage suggestions, businesses can extend the life of their flooring and continue to protect their valuable equipment from static damage. For more information or to request a custom quote, feel free to contact us.

RELATED

RELATED

RELATED

RELATED

Copyright © 2025 Guangdong Yuelai Floor Technology Co., Ltd. All rights reserved

SitemapThis website uses cookies to ensure you get the best experience on our website.